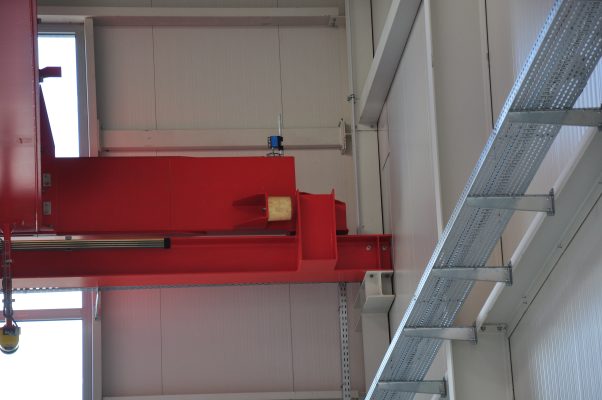

Voith guide rollers and buffers

Reduction of wear – for the life of a crane

In order to avoid wear on the wheel flanges and to reduce the load on the crane runway, generously dimensioned guide rollers are installed on one side of the crane bridge. The narrow guide takes place on one side of the crane runway so that the opposite chassis can move without constraining forces. The guide rollers can be adjusted on one side via defined, machined surfaces and twisting of the guide roller shaft. This ensures that after the guide rollers have worn down, the geometry of the guide rollers is again precisely aligned with the wheel geometry, even after readjustment. By default, cellulose or rubber buffers are used as shock absorbers for the crane bridge. Hydraulic buffers are available as an option.

Guide roller balancers are provided for the toughest applications. This enables larger, horizontal forces to be introduced by distributing them to several rollers, since the roller diameter is usually limited due to the geometric situation on the crane runways.

Deutsch

Deutsch